Products Material - Nonwoven Fabric |

| Author : YX-NEWS DEPARTMENT Date : 2018-05-05 16:37:17 |

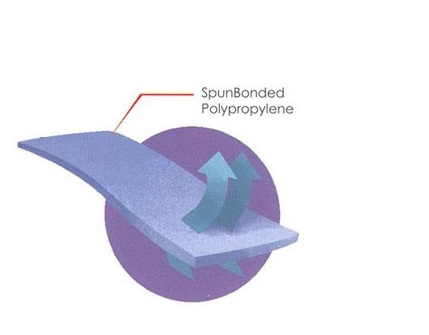

SPP ( SBPP) — Spun bonded Polypropylene

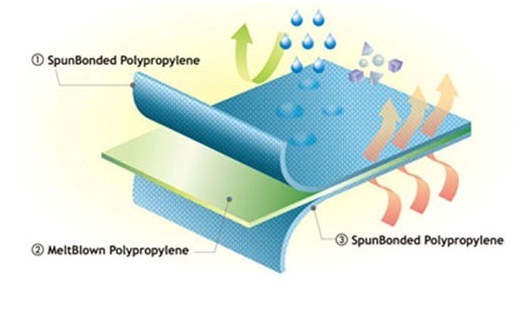

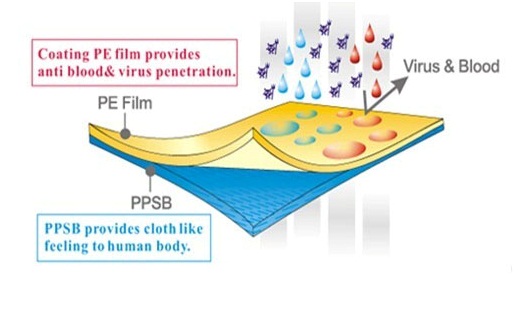

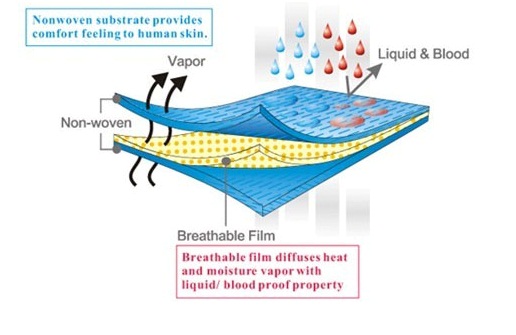

Spun bonded polypropylene is a lightweight, breathable fabric that provides economical protection against non-hazardous, grimy-work environment applications. Spun bonded polypropylene is appropriate for wear in the non-toxic workplace and is a low-cost solution for protecting workers in dirty environments. SPP/PE — Spun bonded Polypropylene Coated Polyethylene SPP/PE is ideal for spray and splatter from water and other non-oil-based liquids and provides economical protection against non-hazardous, grimy-work environment applications. Widely used for protection requires low level of fluid resistant area, which don’t hurt the people, but need waterproof situation. SPP/CPE—Spun bonded Polypropylene Coated Chlorinated polyethylene SPP/CPE (Spun bonded Polypropylene Coated Chlorinated polyethylene) is lightweight, unbreathable, waterproof, and tensile and tear resistance is better than SPP/PE, it is softer than SPP/PE. SPP/CPE is ideal for spray and splatter from water and other non-oil-based liquids and provides economical protection against non-hazardous, grimy-work environment applications. Widely used for protection requires low level of fluid resistant area, which don’t hurt the people, but need waterproof situation. SPES– Spun bonded Polypropylene+ Polyethylene+ Spun bonded Polypropylene SPES is an improvement of SPP/PE, both sides are Spun bonded Polypropylene, which provide comfort feelings to human skin, the middle layer is Polyethylene, ,it is lightweight, waterproof, the surface is not so hard as SPP/PE when the temperature is low, the price is lower compared to SMS. Widely used in high class protection area of medical, industrial, laboratory, electronical, and pharmaceutical. SMS ( SMMS ) — Spun bonded melt blown spun bonded SMS barrier fabric is a unique trilaminate construction that offers a high tensile strength and toughness that is also soft, drapable, and easy to work with. SMS provides a fluid and particulate barrier to protect the worker without sacrificing mobility and comfort. Spunbond layer is consist of continuous filament, with good tensile strength and elongation, Melt blown layer is consist of continuous micro fiber. Specialized SMS In Anti-static, Medical Repellence (anti-alcohol, anti-blood,anti-oil),Extrasoft, Hydrophilic. Garments constructed of SMS fabric are strong and durable, yet offer outstanding comfort, breathability, softness, and wearability.,antistatic, preventing and isolating dust, particle, alcohol, blood, bacteria, and virus invading, widely used in high class protection area of medical, industrial , laboratory , electronical, pharmaceutical. Microporous Film Liminates Microporous film can provide a superior combination of high tensile strength, barrier protection, and breathability. High degree dry particulate holdout to protect against the effects of chemical dusts, paint sprays, asbestos, and other airborne dusts. This line of general purpose protective clothing can be used in any non-hazardous environment where dirt, grime, splashes and spills are present. This fabric is comprised of a microporous film with a nylon scrim between the film and substrate that gives the material additional strength. Microporous film laminate has many characters which are similar or better than Tyvek, such as protection against radioactive contamination. And virus, but the strength is worse than Tyvek, now many fields use Microporous Film Liminates instead of Tyvek for the lower price and similar character. Spunbonded olefin Spunbonded olefin is a spunbonded olefin fabric that is made up of millions of polyethylene fibers that are spunbonded to offer unique qualities of excellent barrier, toughness, and strength in all directions. spunbonded olefin is lightweight and highly resistant to tears and punctures. Protective clothing made of spunbonded olefin repels dirt better than woven cloth garments. Spunbonded olefin provides an excellent barrier against dirt and other dry particulates, including asbestos, lead dust, and radioactive dusts down to sub-micron size. Compared to Microporous Film Liminates, Spunbonded olefin has much higher price. Spunbonded polypropylene (PPSB) Features: Application: Fabric construction:

Spunbonded meltblown spunbonded (SMS)

Polyethylene Coated Polypropylene (PP+PE) Application:

Spunlace

|